Eavision

Eavision is a startup company that focuses on developing modular, quick dispatch agricultural drones. The challenge in this project is that the client has limited budget, so it limits us with alot of design flexibility. As compared with exterior, our client wishes us to prioritize the functional aspect of protecting the drone, and delivery an modular installation and dispatchment for the drone.

Date

Project With

Members

Responsibilities

2023 (1 month)

Wen KunYuan (Lead)

Silvio Consentino (Director)

Ken Chen (Manger)

Lead designer

2D sketch

3D modeling

CNC Prototyping

Launch on Market

All Images and Videos © kunyuanwen

I. Defining the Project

Eavision is a startup company that focuses on developing modular, quick dispatch agricultural drones. The challenge in this project is that the client has limited budget, so it limits us with alot of design flexibility. As compared with exterior, our client wishes us to prioritize the functional aspect of protecting the drone, and delivery an modular installation and dispatchment for the drone.

What this project is about:

To design an aesthetic casing for the drone to protect it from course conditions such as corrosive pesticides and rough terrains.

II. Studying the Structure

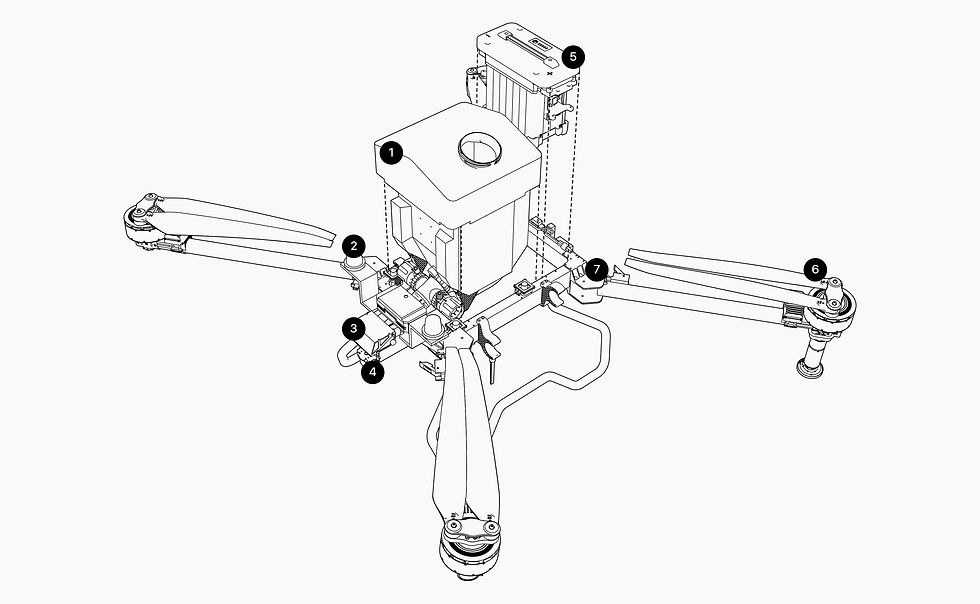

Studying the structure of supplier from XAG, particularly with Agriculture drones, because their modular components are drastically different from consumer drones. The middle section consist of a 65 gallon container unit, with a quadro propeller setup. We can not design it the same way as conventional drones, for instance, the components needs to be exposed, similar to motorcycle, for maintenance and quick access.

Pesticides Container

FPV Transmitter

Lidar Sensor

Modular Battery

Modular Battery

Drone Propeller

Quick Dispatch

III. Production

The product was launched for test site in North America, Indonesia, Turkey and remote regions of Mexico. The model is fully manufactured with ABS plastic and the body container is blow-modeled with high-density polyethylene (HDPE) to ensure maximum strength and light weight. J100 weights just over 54kg, and have a max capacity of 110kg with full tank.