Bosch

Arrow (GDR 18V-215) is a brand new product range for impact driver family line (GDS). This product line comes from the need to design an impact drill that adapt to drilling on different surfaces such as wood, sheet metal, concrete, which we invented kickback™ cruise control to achieve perfect control.

Project With

Date

2022-2023

Members

Wen KunYuan (Lead)

Silvio Consentino (Director)

Ken Chen (Manger)

Neoh Chuh (BOSCH)

Responsibilities

Lead Designer

Exterior Designer

(Selected Concept)

Product Engineering Assistance

Experience Designer

User Researcher

All Images and Videos © kunyuanwen

I. Defining the Project

BOSCH GDR is a series of Impact Drivers for Bosch Professional. This product line cater towards cabinet crew workers, roof top workers and concentrate heavily with the outdoor cordless scenarios. After the success of BOSCH GHO planar, we partnered with Bosch Malaysia again to re-design the experience of GDR series which has not been updated for over 10 years.

What this project is about:

To address the lack of precision control in current impact drivers, where identical speeds are applied to both wood and metal, often causing surface cracks or over-driving when the flush angle is missed.

II. The Problem & Solutions

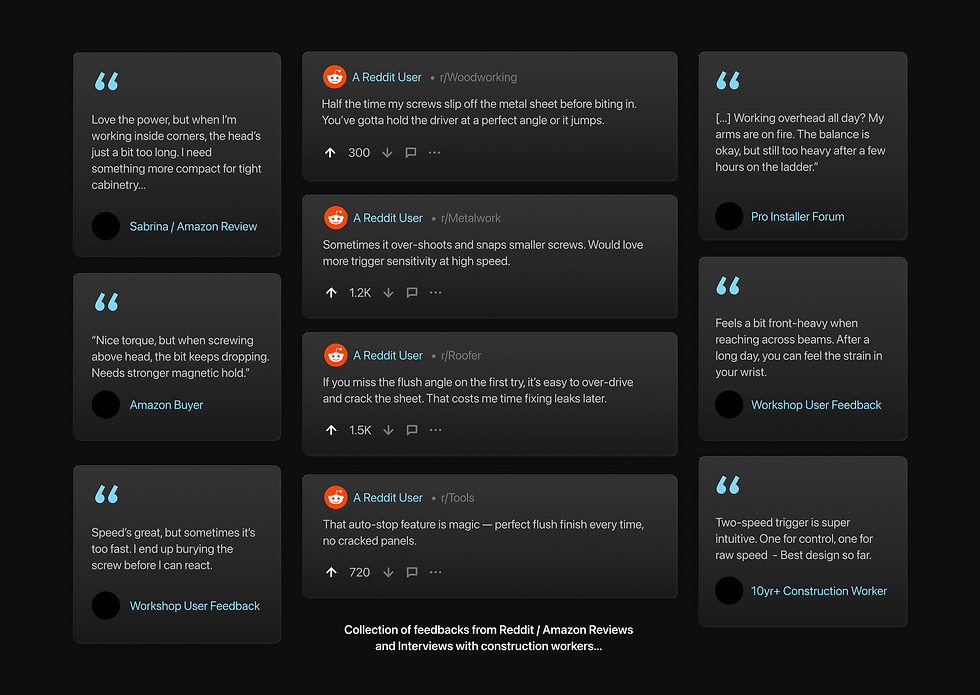

After reviewing the purchase comments online and interviewed with a dozen of woodshop workers, we concentrated on couple painpoints that were mentioned constantly throughout the interview:

Problem:

Current power tool on the market doesn’t differentiate the usage between drilling on wood and on metal. The speed is course, and causes cracks or known as “over-driving” when flush angles are missed.

Solution:

HMI that allow user to adjust between wood and metal. Varying speed depending on the angle that the driver is flushing in, and slows down when fully flush

Problem:

Drill head’s just a bit too long. I need something more compact for tight cabinetry... The balance is okay, but still too heavy after a few hours on the ladder.

Solution:

More compact design that focus on reducing the Drill head size, adding more cushioned rubber TPE towards the rear end to support the pressure when pushing on it.

III. 2D Sketches

We sketched multiple iterations of the new product design, making the drill head significantly more compact (about 40–50% smaller than its predecessor) and repositioned the motor and cooling system closer to the base of the handle. The design concepts were developed in Adobe Photoshop, with the user interface created in Illustrator.

IV. Engineering

One of the main challenges in collaborating with engineers was optimizing the air-vent distribution between the inflow and outflow paths. To achieve a more compact head, we relocated the cooling unit to the base of the handle, which reduced the available space for the back cap. Additional difficulties arose with the metal gear connection to the main body, as the molding process required larger draft angles than initially anticipated.

Final rendereing was done in Keyshot 11.

V. Prototype

After the first round of engineering was completed, we 3D-printed the product casing to evaluate its ergonomics and overall feel. Ergonomics were a key priority for Bosch, which has developed an entire series based on optimized grip and handling standards. Bosch was very pleased with the prototype, and after a few revisions to the overall length, the design moved closer to its final form.

VI. Final Renderings

The final product was launched seven months after we finalized the design and engineering schematics. Released as the Bosch GDR 18V-215, it became an immediate success—earning a 4.8 / 5.0 rating on Amazon, with North America serving as the primary distribution region.