Aiper

Aiper marks a strategic alliance with the world’s foremost maker of aquatic robots, yielding a dual-vent, dual-motor pool cleaner that roams entirely on its own. Guided by on-board intelligence, the unit glides across floor and walls, then docks to a self-charging base that folds seamlessly into any smart-home network. Engineering and industrial design advanced in lock-step—vent geometry, motor synchrony, and housing architecture refined through iterative sprints. This project will showcase entirety from product management, strategic design and market launch.

Project With

Date

2024

Members

Wen KunYuan (Lead)

Ken Chen (Project Manger)

Responsibilities

Lead Designer

Lead Exterior Designer (Selected Concept)

Product Engineering Assistance

Industrial Design

All Images and Videos © kunyuanwen

I. Background

Aiper is a leading maker of cordless robotic pool cleaners. Its Scuba units tackle nearly any pool shape, using twin roller brushes and up to 8 500 GPH suction to lift leaves, algae, and debris. Smart mapping lets the robot scrub floors, walls, and waterline, then self-dock—so owners simply drop it in and relax.

Priced at $800, Aiper’s Scuba X1 Pro automates tasks that cost about $498 per manual clean. A nine-motor powertrain drives dual-vent, dual-brush suction, while OmniSense vision and obstacle-evasion cameras map the pool. The robot vacuums debris, scrubs algae, scales walls to the waterline, and self-docks—delivering comprehensive cleaning without labour.

II. Market Research

Aiper’s Scuba line has consistently out-performed rivals, holding roughly 18 % of the global robotic-pool-cleaner market in 2024—$195 million in sales against a $1.1 billion sector. (Global Market Insights Inc.) Our benchmark chart normalises each key function: Scuba leads in wall coverage, leaf capture, and floor sweep, yet trails peers in water-line scrubbing and fine-particle filtration. These two gaps now frame the brief for Scuba X1: re-engineer suction paths and brush geometry to polish the waterline and refine micro-filter media.

Key pain points include device malfunctions (24%) and filter blockages (19%), which affect performance, along with challenges in cleaning pool corners and the waterline (9–23%). Suction power and coverage (15–20%) are also areas of concern. Customers value ease of use and quick setup (26%).

User-journey maps that owners struggle first with the 33-lb unit’s lift-and-drop routine. Second, they cite inconsistent waterline coverage as the primary performance gap. Lastly, interviews highlight a desire for a water-line cleaning robot. Currently, all completive robots are only able to clean the bottom of the pool.

III. Designing Features

Concept 1 to 4 are ideas that we brainstormed with the Aiper engineering Team. The core upgrade included designing an rotatable thrust that can help the robot to "float" and "surface" while on the waterline.

The design concept of scuba X1 is to use a rotary air vent to propel the robot forward (when floating) and upward (when climbing the wall). To do so, we need to ensure that there is opening slot in all three directions, the front, the top, and the back.

IV: Initial Design

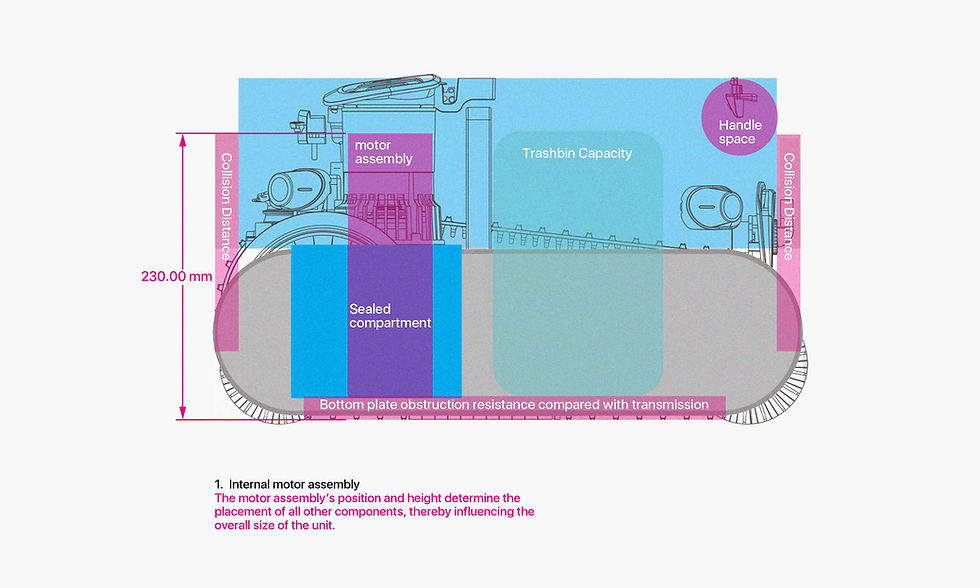

Our initial prototype felt overbuilt—the wheel-to-body ratio read as a miniature “tank,” heavy rather than agile. To convey intelligence and speed, we need a more compact silhouette. We’re revisiting the internal architecture, stacking components diagonally and nesting drive modules to shrink overall volume while protecting performance.

We studied the porportion of automotic vehicles to understand what the ratio between the wheel and body should be. Currently, our tech pack looks like an MPV with max capacity, but instead, we should ballance it between an small sedan similar to Tesla Model 3

By realigning core modules, the new layout trims overall height by 100 mm, cutting volume about 20 %. The steering unit now nests within the sealed-battery bay, freeing space above while preserving service access. Raising the track belt tightens the wheel-to-body ratio from 1 : 2.2 to 1 : 1.5, giving the silhouette a leaner and dynamic shape.

We raised the nose and tapered the tail, lending forward thrust and sleek coupe; a rear handle recalls the Porsche 911’s vision. A slimmer chassis frees space to showcase the rotary nozzle. The debris bin now slides out, replacing a bulky cartridge and further shrinking volume while refining the silhouette.

Together with the client, we selected this concept. Its streamlined shell evokes an autonomous submersible, precisely the impression we sought. The sculpted side vents echo that form yet are strictly functional, accommodating the rotary intake-and-exhaust system that powers the cleaner.

V: Engineering

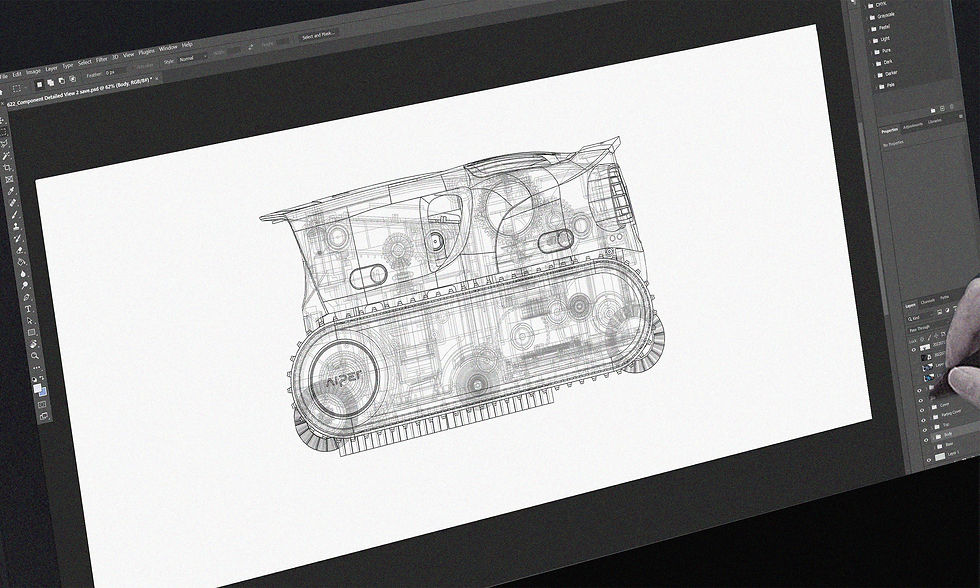

The initial exterior cover is designed in Rhino using Subdivision subsurface. This ensures that complicated geometries and surfaces is measured with precise grade A surface. The surface is then exported and engineered in Solidworks.

VI: Rendering

Keyshot Renderings of Scuba X1 Pro Max. After effect edited in Photoshop.

VII: Visualization

Dust Collection

The frontier flap open when detected leaves, debris and store it in its cabinet when surfacing on the waterline.

©Copyright Aiper. Photo Image of Product in Details

VIII: Launch on Market

Final Design Launch on Maket