Bosch

The Bosch Planar GHO 185V-Li project reflects Bosch’s commitment to expanding its cordless tool portfolio through UX-led product innovation. By interviewing over 18 workshops, we uncovered critical user pain points: uneven planing and slow blade changes. Our design introduced a displacement sensor for precision and a magnetic TCT blade system that cut changeover time dramatically. Leading this project from concept to prototype, I shaped a solution that merges user-driven insight with Bosch’s product line.

Project With

Date

2022-2023

Members

Wen KunYuan (Lead)

Silvio Consentino (Director)

Ken Chen (Manger)

Christof Lahner (Manager)

Neoh Chuh (BOSCH)

Responsibilities

Lead Designer

Exterior Designer

(Selected Concept)

Product Engineering Assistance

Experience Designer

User Researcher

All Images and Videos © kunyuanwen

I. Background

The Bosch Planar GHO 185V-Li project represents Bosch Power Tools’ strategic initiative to expand its cordless product line through a new vision of UX-led product innovation. Tasked with redefining the professional woodworking experience, our team approached this challenge by engaging directly with over 18 woodworking workshops, gaining deep insights into the persistent frustrations of professional carpenters.

In a series of immersive field visits, we received insights from one-on-one interviews with carpenters across local workshops, documenting their workflow, habits, and frustrations. We gathered empirical insights grounded in lived experience. Two issues emerged as universal pain points: the struggle to achieve consistently flat planed surfaces, and the time-consuming blade replacement process.

Insight 1: Uneven surfacing causes significant amount of time to replank and smooth out.

Insight 2: It is hard to make a perfectly flat wood. Carpenter rely on external tools to keep their wood flat.

Insight 3: Blade sharpening process takes 15 minute. Repetitive and annoying.

II. Ideation

Rethinking about blade changing process. Previously users had to take blade out to sharpen it with a whetstone. This process would take 15 minutes. The new slim blade replacement design elimates the whetting process, improving blade-changing efficiency by 87%

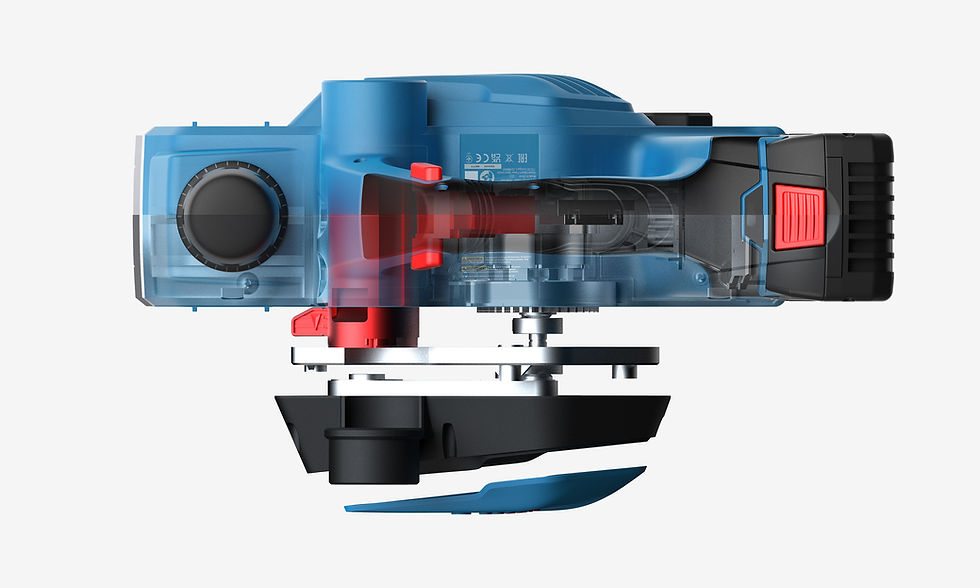

The new magnetic TCT system replaces the traditional HSS process, where carpenters had to manually remove and sharpen blades with a whetstone. With instant-replaceable TCT blades, carpenter can instantly replace worn blades in less than 20 seconds.

For a better user experience, we also embedded a battery display to capture the real-time usage and compute an expected battery level while using GHO. From BOSCH's research, majority of the time, the tool is spent outside, therefore, the need to accurately display battery level and provide actionable feedback becomes inherently imperial.

III. 2D Sketching

EXPLORING THE FORM WITH THE HELP OF SUBDIVISION SUBSURFACE WITH RHINO 7.

IV. 3D Manufacture

2D sketches were translated to 3D design modeled in Solidworks following 3° draft angle for ABS constraints. Usually for power tools, the draft angel is larger because the wall thickness is greater (>2.8mm). The design follows design for manufacturing principle to minimize assembly parts.

From early conceptual sketches to CAD development and ergonomic 1:1 testing, the project was a comprehensive exercise in experience-driven product design. As lead designer, I guided the project across all phases—from form exploration and CMF detailing to cross-functional collaboration with engineers, manufacturing experts, and tool specialists.

V. Market Launch

BOSCH GHO 185v-Li is delivered to market after 8 month from sketch to market production.