Bosch

BOSCH 18V -450HC (CN) / BOSCH 18v - 330CN (US) is an in-house project we did with BOSCH-PT Malaysia engineering team to design the most "compact" yet "powerful" torque on the market. The design exceed market competitor such as Makita and DeWalt with 800 Nm and 2,300 RPM. To achieve this feature, we had to innovative the engineering design and spatial constraints

Project With

Date

2022-2023

Members

Wen KunYuan (Lead)

Ken Chen (Manger)

Neoh Chuh (Product Manager)

Responsibilities

Lead Designer

Lead Exterior Designer (Selected Concept)

Product Engineering Assistance

Experience Designer

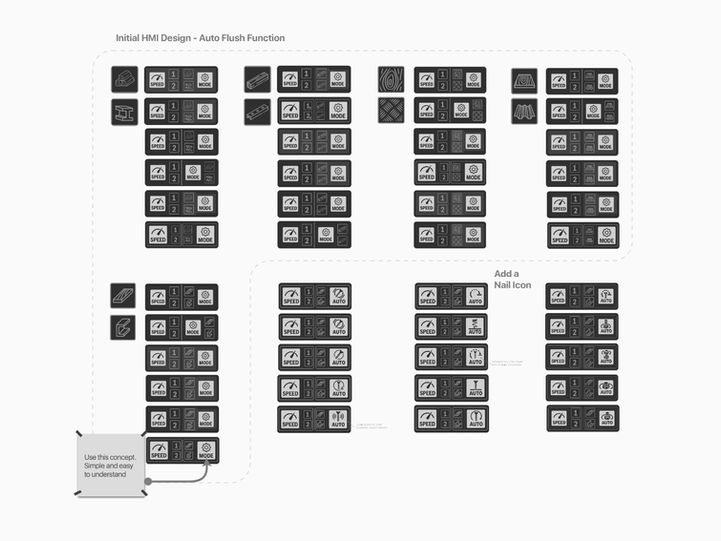

UIUX / HMI Designer

All Images and Videos © kunyuanwen

I. Background

Heavy Duty service worker complained about the lack of torque, ergonomic and compactness of the predecessor GDS18V, which is manufactured 8 years old, in the new automotive manufacturing environment. BOSCH-PT had tasked to conduct an thorough design oriented upgrade to their current product line, aiming to create the most compact, yet highest torque wrench driver on the market. In order to accomplish this challenging task, we partnered with BOSCH PT engineering team Malaysia to innovate engineering challenges and spatial constraints.

II. Field Visit

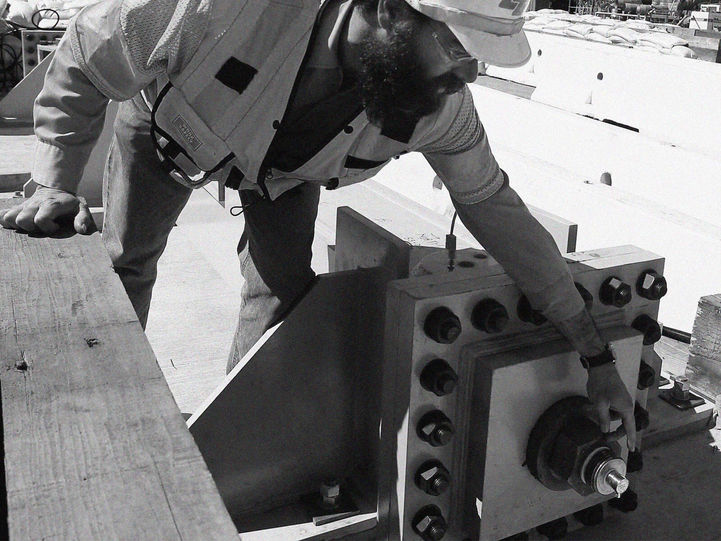

The Stormbreaker project emerges from a deep request into the evolving demands of industrial bolting. The objective was to craft a cordless impact wrench that aligns with the physical realities and nuanced needs of professional users across automotive repair, infrastructure maintenance, and heavy machinery assembly. Through user research, we mapped out users in two different segments

-

70% indoor in car repair stores(messy and greasy)

-

30% outdoor for car repair/rescue

Through direct engagement with technicians working in varied conditions—car garages, rail sites, construction scaffolds—we traced a recurring narrative: exhaustion. The bulk and imbalance of conventional tools amplify strain over extended sessions, often resulting in dropped devices and diminished productivity. In response, the Stormbreaker integrates a rebalanced motor configuration with a center of gravity aligned at the hand. At just 1.6kg, the form delivers 850Nm of torque with a compact 160mm head—achieving a rare fusion of force and finesse.

-

Working area: Bolt installation on elevated beams.

-

Posture challenge: Tasks involve prolonged overhead arm use; lighter tools are needed to reduce fatigue.

-

Usage frequency: Infrequent, around 10% of total tasks, but physically demanding.

-

Spatial constraint: Pipe or joint areas are too narrow—current tool head sizes do not fit.

III. 2D Sketching

BOSCH hand-drawn sketch on Adobe Photoshop. Sketch is completely done with hand digitally without usage of AI tools.

IV. Engineering

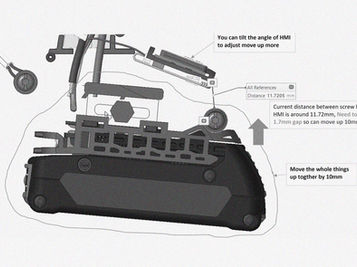

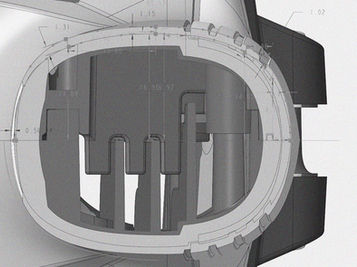

Engineers work with us simultaneously on the tech-pack ("skeleton") layout of the drill. They would adjust accordingly to our sketch dimension on which type of modules to use. For instance, they adjusted to an electronic KEDU-25D switch for more compatibility, and used a 18V battery back to supply higher demand of air-flow needs. The PCB was also adjusted closer to the bottom so it has better heat-dissipation.

V. 3D Manufacture

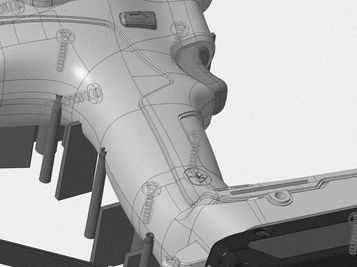

Engineering: Working around issues of mass production, some common issue we faced includes draft, molding angle, PCB placement, Battery overheating, airflow simulation, bolting, ribbing structural analysis and regulatory constaints

VI. Physical Prototype

Left: Final Prototype CNC with Foam to understand the scale and overall scale. Right: Predecessor GDS, used for scale to show scale and size comparison. Overall increased horizontal length by 30%, while increasing torque from 300nm to 700nm.

VII. Launch to Market